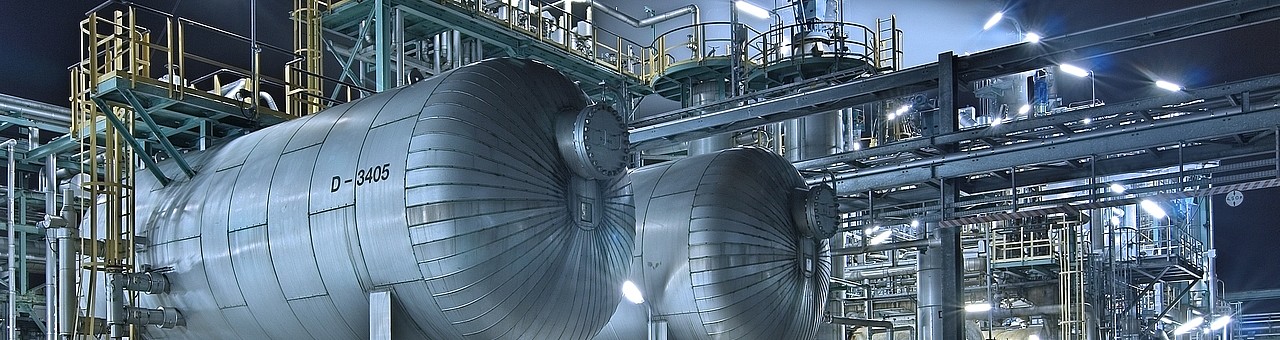

SAMSON offers standard and custom-engineered solutions for steam conditioning to meet the requirements of a wide variety of industrial applications. Steam conditioning valves are standard compact units to reduce the temperature as well as regulate the pressure of steam for specific requirements and steam demand. Cooling nozzles are a cost-effective and rugged solution in applications that only require temperature control. Water bath desuperheaters (saturated steam generators) are the right choice for converting superheated steam into saturated steam with extremely precise temperature control.

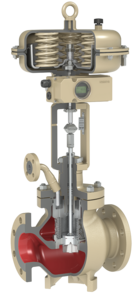

One unit to reduce both the steam pressure and temperature

Steam conditioning valves

- Maximize process efficiency by using steam near the saturation temperature

- Minimize the cost of investment as the injected cooling water does not need to be preheated (depending on the process conditions)

- Protect the downstream piping and equipment against excessive pressures and temperatures

A variety of nozzle types, such as maintenance-free fixed orifice or controllable nozzles, suitable for temperatures down to –196 °C in LNG and process gas applications

Spray nozzles

- Provide rugged, reliable and cost-effective steam cooling in industrial applications

- Available as a turnkey system with automation or in combination with SAMSON cooling water valve and industrial controller

- Optionally with cyclone separator, pipeline drains and instrumentation

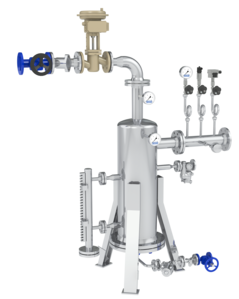

The only technical solution to safely generate saturated steam conditions

Water bath desuperheaters

- For installations where only superheated steam is available, but a reliable supply of saturated steam is required

- Provide extremely precise temperature control

- Suitable for small quantities of steam

- Make it possible to implement temperature control circuits in safety-instrumented systems (SIL)